Installation

Polybutylene piping systems have revolutionised how pressurised hot and cold water systems are installed. No bending tools, no flame, no fluxes, no chemicals.

Simple, fast and efficient

Piping systems from Polybutylene have revolutionised how hot and cold water pressurised systems are installed. With the installation of Polybutylene piping, no bending tools are needed, no naked flame, and no fluxes or chemicals.

Polybutylene offers improved handling due to its flexibility, reduced pipe wall thickness and low memory effect. In addition to the potential cost savings of faster installation, Polybutylene pipes provide opportunities for installation in tight, cramped spaces.

Pipework of up to 50mm in diameter is supplied in lightweight and easily handled coiled lengths of up to 500 metres. Installations can be made in suspended floors from below before ceilings are fitted and flexible Polybutylene pipe can be cabled around obstructions and through joists. Continuous, flexible pipe means fewer joints providing greater system integrity.

With Polybutylene, many installations can be made without accurate pre-measuring, since it is easy to measure and cut in situ. Also, the light weight and ease of handling of Polybutylene piping allows factory pre-fabrication and rapid on-site installation when timing is critical such as installations in cruise ships.

Performance

Polybutylene piping systems will not scale-up in hard water areas or corrode in soft water areas.

Significant performance benefits

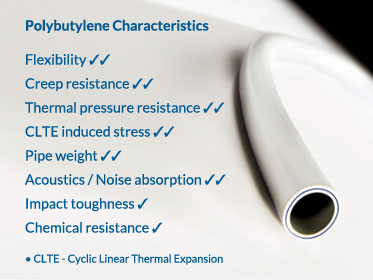

Polybutylene piping systems have an array of performance advantages which have made the material the latest generation choice for piping systems.

Performance benefits include lower thermal diffusivity than copper pipes which means water takes longer to freeze in them during cold weather.

If freezing does occur, the pipe expands to take account of the added volume, returning to its normal dimensions when the thaw comes. The same Polybutylene thermal characteristic operates in reverse making them cool to the touch, even when high temperature water is being transported.

Polybutylene piping systems will not scale-up in hard water areas or corrode in soft water areas. They absorb and suppress sound, rather than transmitting it (Case study: Royal Albert Hall) and they are not subject to 'water hammer' particularly in areas noted for high water delivery pressures.

Polybutylene piping systems will not scale-up in hard water areas or corrode in soft water areas. They absorb and suppress sound, rather than transmitting it (Case study: Royal Albert Hall) and they are not subject to 'water hammer' particularly in areas noted for high water delivery pressures.

A plastic pipe system consisting entirely of Polybutylene is possible, due to the variety of jointing techniques to connect Polybutylene pipes to fittings. Typical jointing techniques include push-fit, crimping, electro fusion, socket fusion and butt fusion for large diameter pipes.

Welding technology with Polybutylene offers additional opportunities to pre-fabricate sections off-site reducing logistical complexity and installation time.

Long-term ISO 9080 tests performed on Polybutylene pipes project service lifetimes of 50 years or more for Polybutylene hot water pipes operating with water at 70°C, at 10 bar pressure. ISO 9080 tests are carried out according to international protocols by independent and accredited test agencies such as EXOVA.

| Features | Application | Polybutylene (Polybutene-1/PB-1) |

|---|---|---|

| Density | Lower weight: facilitates handling, decreases the cost and reduces the environmental impact of its manufacturing process. | Plastic systems in general benefit from its lightness compared to metal. |

| Thermal Conductivity | It reduces heat loss and the possibility of condensation on the cold side. | Again it is a typical characteristic of plastic systems, where PB has the lowest value. |

| Thermal Expansion | The expansion of plastic materials due to temperature changes is greater than that of metal: It must be taken into account for their compensation. | Although Polybutylene has a lower expansion than other plastic materials, these expansions must always be taken into account. |

| Elastic Modulus | The much lower rigidity of the piping (lower elastic modulus) facilitates its usability in construction, and reduces the generation of stress linked the functioning of the installations: water hammer, fixed points and expansion, etc. | It is the most elastic material of all those used for this application, and therefore it is the most manageable and generates the lowest stress. |

| Resistance to Pressure and Temperature | The main characteristic that defines a piping system is its resistance to temperature and pressure. This information is characterised in the regression curves of the material, the DNA of the pipe. | Polybutylene is the material with the best pressure resistance according to the temperature. This leads to lower thicknesses for the same required resistance, or a better resistance for the same thickness. |

| Creep Resistance | Creep represents the deformity of the material over the course of time under constant load. It is fundamental in compression joints to ensure the dimensional stability of the pipe. | Polybutylene has minimum creep, preserving its dimensions under constant load. |

| Transmission of Sound | As the material is very elastic, the transmission of sound and therefore noise through the physical medium made up of the piping network is far lower than that of other materials. | It is the material that best insulates against noise transmission. |

| Expansion Stress | The low elastic modulus of the material means that the stress generated by the expansion between fixed points of the installation is much smaller. | Polybutylene does not cause problems in installations due to expansion stresses. |

| Water Hammer | The pressure peaks caused by instantaneous shut-offs of fluid flow are sources of problems in rigid piping systems. | Polybutylene is excellent at absorbing the stress associated with water hammer in installations. |

| Sustainability | Sustainable construction requires systems manufactured with a lower consumption of resources. | Polybutylene is the system that consumes less resources in its manufacture than metals or other plastics and causes less harm to the environment. |

Environmental

Environmental impact study of piping materials by the Technical University of Berlin rated the impact of Polybutylene as low.

Polybutylene classed as "environmentally friendly"

Piping systems' environmental impact in areas including landscape scarring, emissions into the atmosphere, soil and water – and recycling potential are assessed in ‘cradle to grave’ studies. Such a study was conducted by the Technical University of Berlin on various drinking water pipe systems, including galvanised steel, copper, and plastics: cross-linked Polyethylene (PE-X), Polypropylene (PP-R), Chlorinated Polyvinylchloride (PVC-C) and Polybutylene (PB-1).

For all comparative indices, Polybutylene was rated as one of the products delivering the lowest levels environmental impact. Polybutylene is regarded highly in the area of sustainability, demonstrated by demanding national and international standards, and extensive long-term testing. Polybutylene is classed as 'environmentally friendly' – consuming less energy during manufacture, conversion, installation and use than its competitors. As a non cross-linked polyolefin raw material, it can also be recycled.

Reliability

Chlorine Resistance

Polybutylene pipes are expected to have service lifetimes of 50 years when exposed to water containing 4 ppm chlorine at 60°C. Moreover Polybutylene pipe has been shown to perform for >1,000 hours in chlorine content of 30 ppm at 30°C/6 bar (Test Report-No. PB 1087C, Infraserv Höchst Technik, 2004).

Independent test results – Long-term reliability and chlorine resistance

ASTM F2023 test report obtained for LyondellBasell's Akoalit PB 4267 confirming more than 50 years extrapolated lifetime at continuous use at 60°C and a chlorine concentration of 4 ppm. download

Uninterrupted pressurised operation for up to 50 years and counting

Polybutylene pipe applications installed in Europe for underfloor heating (since the early 1960s) and district energy (since the mid 1960s) are still operating successfully.

Polybutylene pipes were installed in the Vienna Geothermal Project in 1974, replacing metal pipes which proved unsuitable due to rapid corrosion and operated until 2010 when an updated system was installed. The Vienna Geothermal project utilises very aggressive geothermal water as the heating medium. The Polybutylene piping system ran continuously for 36 years at a constant temperature of 54°C and a pressure of 10 bar until replacement due to system reconfiguration.

Polybutylene piping systems are specified increasingly in well-known major products and locations as: Royal Albert Hall, Canary Wharf, Imperial War Museum North, Säntis 2000

Independent test results – Assessment of Polybutylene Plumbing Installation after 18 Years of Service

Presented at Antec 2013 – independent study (onsite evaluation and lab testing) of the condition of a Polybutylene (PB-1) plumbing system in a multi-unit apartment complex. download

Polybutylene is not sold by PBPSA members for use in pipe applications intended for use in North America, and those parties require their customers or distributors not to sell products made from PB-1 into pipe applications for North America.